|

|

11/02/2010 |

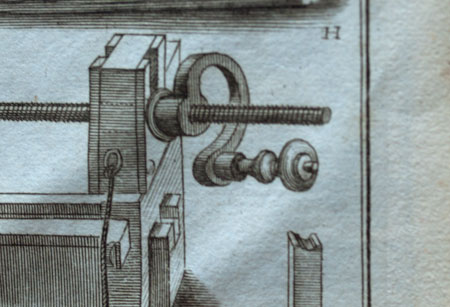

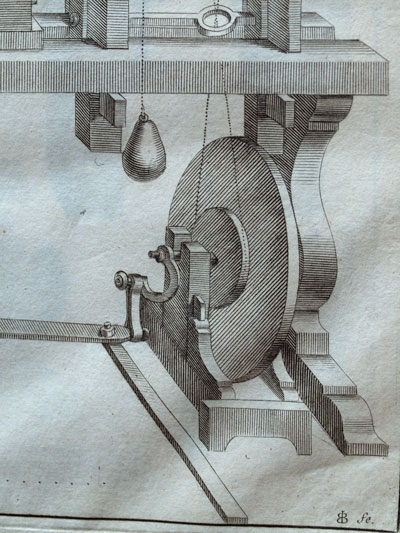

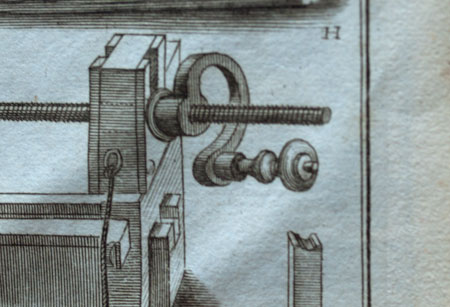

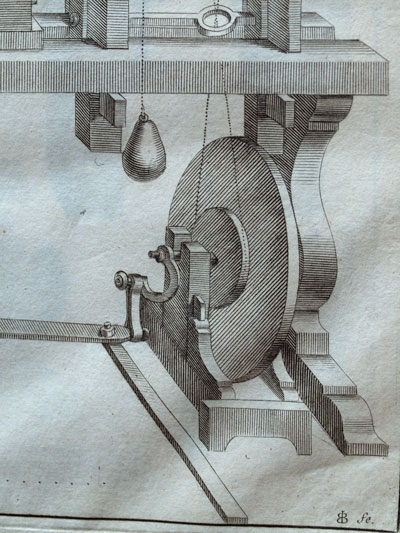

I got called to the back of the shop a few days ago where some of my colleagues were having a heated discussion about crankshafts. They were perusing a copy of Charles Plumier's 1701 L'Art De Tourner, Ou De Faire En Perfection Toutes Sortes d'Ouvrages Au Tour and one wag noticed that all the crankshafts in the pictures weren't connected to either a flywheel or a screw by a straight rod, like in a steam engine, but a "U" shaped arm instead. The question that they were asking me was why, I had no idea, and we spent most of the afternoon tossing theories around and making cryptic drawing on the whiteboard to explain what we were talking about. I got called to the back of the shop a few days ago where some of my colleagues were having a heated discussion about crankshafts. They were perusing a copy of Charles Plumier's 1701 L'Art De Tourner, Ou De Faire En Perfection Toutes Sortes d'Ouvrages Au Tour and one wag noticed that all the crankshafts in the pictures weren't connected to either a flywheel or a screw by a straight rod, like in a steam engine, but a "U" shaped arm instead. The question that they were asking me was why, I had no idea, and we spent most of the afternoon tossing theories around and making cryptic drawing on the whiteboard to explain what we were talking about.

The following theories were proposed:

- It looks more elegant - maybe.

- It makes for a stronger casting - not in 1703 - the arms were forged - "S" casting spokes came later.

- It was easier to turn because the U protected your arm - maybe but isn't a wood disk easier to make and cheaper?

- The spring action made the handle more forgiving - I'll buy that.

- The spring action in the "U" shape acts like a mini transmission making for smoother and easier starts and stops and in the case of a screw allows for smoother action if there are variable amounts of resistance when turning the screw. This is the reason I like the best - solid engineering.

Tim said it best "It's a sweeter action" and he's right. That a vast number of foot and hand powered crankshafts are shaped this way means that the "U" design was an accepted standard form of construction. Individual craftsman might not have understood the engineering of springs and inertia, or the nuances of ergonomics, but taken as a package, as a group, the design must have been thought "sweeter" or they would have not wasted the extra material. Tim said it best "It's a sweeter action" and he's right. That a vast number of foot and hand powered crankshafts are shaped this way means that the "U" design was an accepted standard form of construction. Individual craftsman might not have understood the engineering of springs and inertia, or the nuances of ergonomics, but taken as a package, as a group, the design must have been thought "sweeter" or they would have not wasted the extra material.

I am not aware of any historical information on why cranks should look like this, but I haven't looked yet either - it might be out there staring me in the face. I am curious if you can think of any other reasons to make a crankshaft in this form, or if you know of any documentation. But for now at least - fun is over - it's time to get back to work.

|

Join the conversation |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

I got called to the back of the shop a few days ago where some of my colleagues were having a heated discussion about crankshafts. They were perusing a copy of Charles Plumier's 1701 L'Art De Tourner, Ou De Faire En Perfection Toutes Sortes d'Ouvrages Au Tour and one wag noticed that all the crankshafts in the pictures weren't connected to either a flywheel or a screw by a straight rod, like in a steam engine, but a "U" shaped arm instead. The question that they were asking me was why, I had no idea, and we spent most of the afternoon tossing theories around and making cryptic drawing on the whiteboard to explain what we were talking about.

I got called to the back of the shop a few days ago where some of my colleagues were having a heated discussion about crankshafts. They were perusing a copy of Charles Plumier's 1701 L'Art De Tourner, Ou De Faire En Perfection Toutes Sortes d'Ouvrages Au Tour and one wag noticed that all the crankshafts in the pictures weren't connected to either a flywheel or a screw by a straight rod, like in a steam engine, but a "U" shaped arm instead. The question that they were asking me was why, I had no idea, and we spent most of the afternoon tossing theories around and making cryptic drawing on the whiteboard to explain what we were talking about.  Tim said it best "It's a sweeter action" and he's right. That a vast number of foot and hand powered crankshafts are shaped this way means that the "U" design was an accepted standard form of construction. Individual craftsman might not have understood the engineering of springs and inertia, or the nuances of ergonomics, but taken as a package, as a group, the design must have been thought "sweeter" or they would have not wasted the extra material.

Tim said it best "It's a sweeter action" and he's right. That a vast number of foot and hand powered crankshafts are shaped this way means that the "U" design was an accepted standard form of construction. Individual craftsman might not have understood the engineering of springs and inertia, or the nuances of ergonomics, but taken as a package, as a group, the design must have been thought "sweeter" or they would have not wasted the extra material.

One possibility is that when the crank is loose and left to hang by gravity, the bend could be used to put the handle or pedal in the best position...

Z

If I was hand forging an arm like this, I can easily see why it's easier to put a curve in the arm....adjustability.

Having a curve allows the maker to adjust the distance between the two pivot points to exactly where he wants it, or exactly as the application requires.

If it were a straight arm, it wouldn't be impossible to lengthen or shorten the arm if it were "off", but it would be a whole lot easier to ease or tighten the curve to achieve the same effect.

Wesley

http://www.flickr.com/photos/7864355@N06/514857796/in/set-72157600269118170/

Wesley

Regards,

FK

Stephen